Mechanical Design

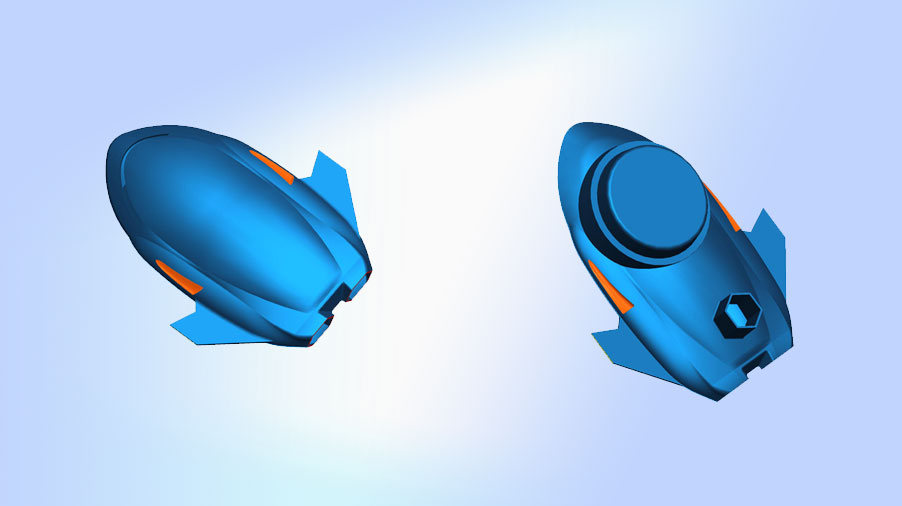

Product Design

TSD’s core strength lies in design to manufacturing projects using high end CAD/CAM/CAE technologies and implementation of technology driven initiatives in desired design intent facilitates best design in right time to market with competitive cost.

TSD executes product design projects by debugging existing design and manufacturing principles of competitive products in the global market with next generation mind set, proven market analysis with out of box thinking , new concept generation techniques and partnering with next generation technology partners.

We derive the product concept with culmination of VA/VE, Cost & Quality Engineering principles ,adhering to the best global quality design and manufacturing systems/standards - FMEA, DFMEA, PFMEA, DFA, DFS, DFM to ensure minimum iteration of simulation of design using 3D printing, Vaccum Casting, prototyping, tool design, manufacturing technologies for faster design iterations, testing and customer approval and to achieve desired design intent in accordance with world class design attitude, principles and standards of design.

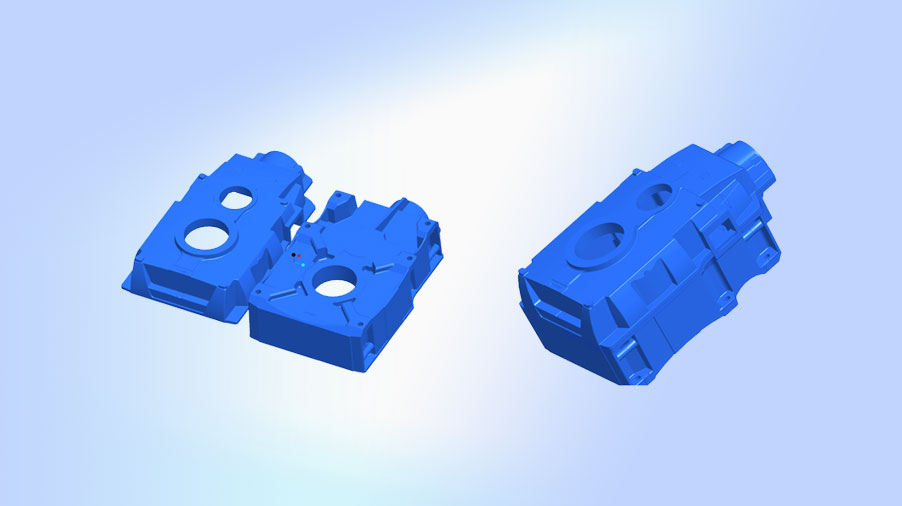

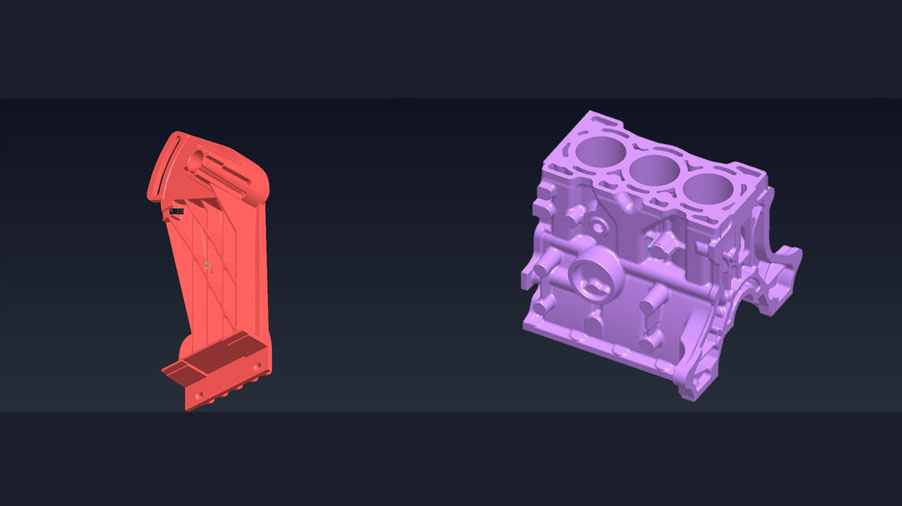

Legacy / CAD data migration

TSD leverages product development expertise for mission critical components for Automotive / Appliances / Marine / Consumer Electronics / Electrical Automation / Industrial Electricals industries in executing Legacy CAD Data Migration projects.

TSD specialized in executing projects for Global Engineering & Technology Centres for their critical onsite/offsite requirements with robust parametric modeling standards, in accordance with stipulated customer QA standards, competitive cost and delivery.

TSD team specialized in Robust Parametric Modeling, Assembly, Detailing, Surface Modeling, Advanced Assembly techniques for mission critical OEM manufacturers – Passenger Cars, LCVs, HCVs, Heavy Engines, Marine Engines, Gear Boxes, Home Appliances, Transportation, Mining Vehicles etc.

We have track record for Global Fortune 500 clients Since 2003 supporting their critical requirements in Product Development and CAD migration projects for 250000 hrs.

CAE

TSD has track record in executing CAE projects for European and US clients for Automotive / Appliances OEM’s, Tier 1, Tier 2 suppliers by partnering with proven & renowned niche design institutions/engineering services organizations in India and abroad.

- ANSYS - Linear and Non-Linear Analysis for VA/VE projects for Automotive /Appliances - Global Integration projects.

- LS - Dyna - Automotive / Appliances verticals.

- CFD - Automotive / Appliances verticals.

- MAGMA - Automotive OEM - Simulation for New Generation Engine Block (Cylinder Block).

- Hypermesh - Automotive / Appliance verticals.

- Nastran - Automotive / Appliances verticals.

- ANSA - Automotive.

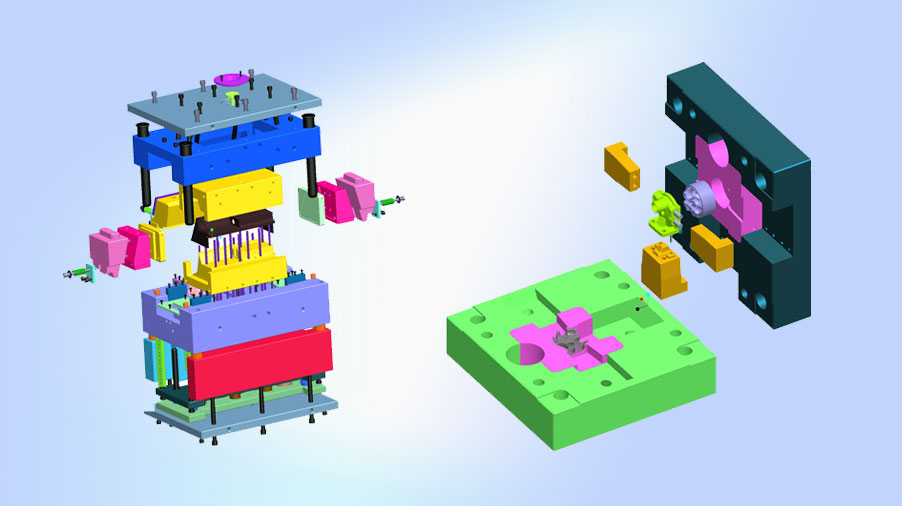

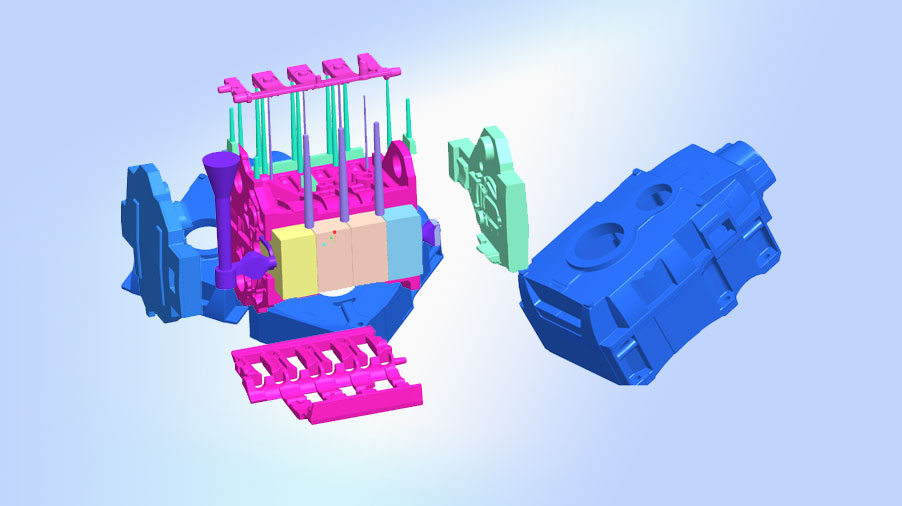

Tool Design

TSD leverages tool design expertise since one and half decades partnering with global Fortune 500 clients, leading corporates, regional and global technology centres, renowned world class tool design institutions - NTTF, CIPET, GTTC, CITD for implementing blend of proven next generation tool design technologies, high-end CAD/CAM/CAE technologies and design quality systems like FMEA, DFMEA, DFM, PFMEA etc.

We undertake following tool design and manufacturing services:-

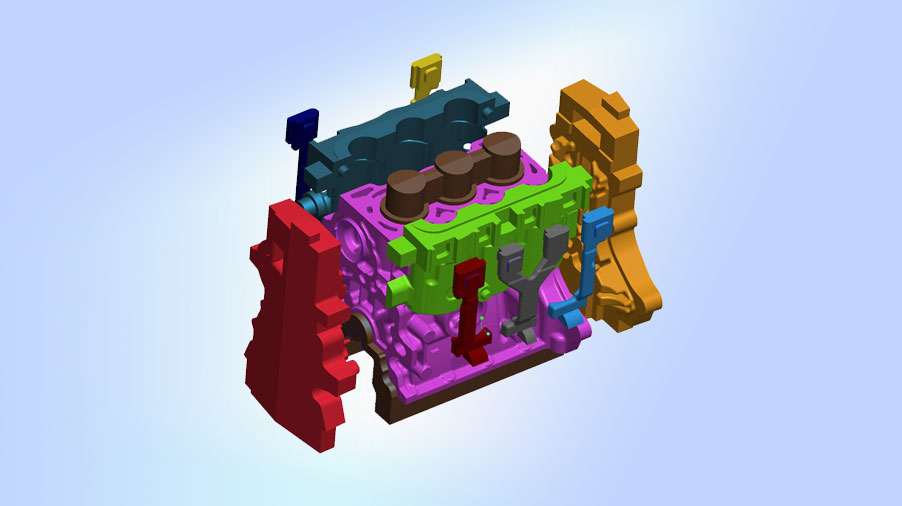

Castings

- CNC Pattern Design and Manufacturing for high-pressure molding, Sand castings for Automotive Cylinder Blocks, Cylinder Heads for heavy engines, Passenger cars, V-Engines, Straight Engines, Manifolds, Differential Housing, Gear Boxes, different mission critical casting components.

- Gravity Die casting Die design/Manufacturing (GDC).

- Pressure Die casting Die design /Manufacturing(PDC).

- Low Pressure Die casting die design/manufacturing.(LPDC).

- Mold Design for Plastic components/Manufacturing.

- Sheet metal die design for Sheet Metal components/Manufacturing.